Designed with the highest level of hygiene and the smallest use of resources in mind

Finding the right cleaning in place (CIP) solution for your plant is essential for the ultimate success of your manufacturing processes. High product quality and safety, increased production time, less downtime for cleaning and environmental efficiency can only be achieved with a CIP system that responds perfectly to your needs.

Our hygienically-designed systems only use reliable components from reputable suppliers and are tailored to customer preferences and requirements. We have two main types of CIP systems.

Flexible CIP System

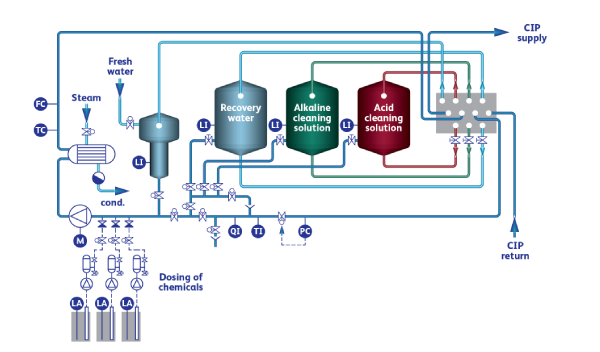

Diversey’s FlexibleCIP design enables each CIP process to ‘take’ only the necessary volume of solution from the appropriate tank. The recovery tank is disconnected from the circulation loop and the object is cleaned by circulating the cleaning solution via by-pass.

Our approach is unique in the industry as we install the dosing and dispensing valves in a ‘cluster’ thus shortening the distance that the cleaning solution is passed through to save on energy and water usage.

Our system design allows for each CIP recipe to be tailor-made with up to 50 targeted parameters to acutely define the cleaning process; different concentrations of solutions can be working at different temperatures, therefore only consuming the chemistry and energy required. The process can be fully optimized even on complicated objects like pasteurizers, fillers and carbon blenders.

The benefits of our system design are:

- Improved flow stability

- Ability to deaerate the system through the static leg in case of cleaning closed circuits

- Prolongs the lifetime of each cleaning solution.

- At least 30% cost savings on freshwater consumption

- At least 25% cost savings on chemical consumption

- At least 20% saving on CIP cleaning time

- Significantly reduced wastewater load

- After start-up engineering/application support

Compact/Mobile CIP System

An alternative solution to the centralised Flexible CIP system, our compact/mobile CIP systems have been developed for use in small production plants with limited space, lines with a low cleaning frequency, aseptic lines or lines/objects with specific hygiene requirements that must be separated from the main CIP system.

Maximum flow capacity: up to 25m3/h at 3 bar

Maximum working volume of the process tank: 800L

When the Compact/Mobile CIP is best

Dairy Industry

Dairy Industry

- Small filling lines (eg. Aseptic, butter machines)

- Homogenizers

- Pasteurizers

Non-alcoholic Beverages

- Micro filling lines

- Process lines for products with a short shelf life

Alcoholic Beverages

- Micro & mini-breweries

- Wineries

Food Processing

- Mixing tanks and lines for sauces and marinades (ready meals, fish in cans)

- Lines for chocolate and caramel

- Lines for pasta production, bakeries

Cleanrooms (Pharmaceutical & Cosmetics)

- Mixing tanks

- Filling machines

Diversey’s CIP Knowledge and Experience

Our expertise comes from over 30 years of experience providing integrated and engineered CIP solutions. We apply that experience to a full analysis of your specific CIP needs, leading to retrofitting, upgrading or fine-tuning existing installations, or the design and implementation of a new, fully integrated CIP system that will revolutionize the speed, hygiene standards and efficiency at your plant.

We continuously invest in evolving our approach to CIP to incorporate new technologies which improve efficiencies and reduce environmental impact.